If your team manages aggregates, coal, scrap, salt, mulch, grain, or any other bulk material, you already know the uncomfortable truth: stockpiles are expensive to measure poorly.

Inaccurate volumes distort inventory valuation, create production planning headaches, trigger procurement mistakes, and invite disputes between operations, finance, and vendors. And traditional measurement methods—survey crews on foot, loader “bucket counts,” or sporadic ground scans—often cost too much time, expose people to unnecessary risk, or simply can’t keep up with how quickly inventory changes.

That’s where LiDAR-equipped drones earn their keep.

This article breaks down (in practical, decision-maker terms) how LiDAR drones work for stockpile reporting, why they’re often more reliable than photogrammetry in tough conditions, what you should demand from a deliverable, and how to deploy drone-based reporting as a repeatable business process—not a one-off experiment.

The Real Problem With Stockpiles: Change, Complexity, and Confidence

Stockpiles don’t behave like neat geometric shapes. They’re irregular, constantly changing, and often located in messy environments:

- Dozers and loaders reshape piles daily

- Moisture changes density and surface texture

- Piles merge, split, and spread into berms

- Windrows and uneven terrain distort baselines

- Conveyor drops create steep slopes and voids

- Operations continue while measurement is needed

Decision makers typically care about three outcomes:

- Speed: How quickly can you measure and report without disrupting operations?

- Accuracy: Can you trust the number enough to base financial and operational decisions on it?

- Repeatability: Will the method produce consistent results month after month, site after site?

LiDAR drones are designed to hit all three.

What LiDAR Is and Why It Matters for Stockpiles

LiDAR (Light Detection and Ranging) measures distance by emitting laser pulses and timing how long they take to return. Each pulse becomes a point in a 3D “point cloud.” Multiply that by hundreds of thousands to millions of points per flight, and you get a highly detailed surface model.

For stockpile reporting, this translates into:

- Clear 3D pile definition

- Accurate pile-to-ground separation

- Strong performance in low-texture or low-contrast environments

- Better results in vegetation-adjacent areas or cluttered sites

- Reliable modeling when imagery struggles

LiDAR vs Photogrammetry: A Useful Way to Think About It

Photogrammetry builds 3D models from overlapping images. It can be excellent—especially in ideal lighting, with textured surfaces, and well-defined edges.

But in stockpile environments, you often face conditions where image-based reconstruction becomes fragile:

- uniform material (dark coal, wet sand, uniform salt)

- harsh shadows from conveyors or high walls

- reflective or glittery surfaces

- dusty haze or low light

LiDAR doesn’t “guess” surfaces from pixels. It measures physical distance directly. That’s why many high-volume sites use LiDAR when they need confidence and consistency across seasons and site conditions.

How LiDAR Drone Stockpile Reporting Works: A Clean, Repeatable Workflow

A professional LiDAR stockpile workflow should look like a production pipeline—not an improvisation.

1) Site Goals and Reporting Definitions (Before the Drone Takes Off)

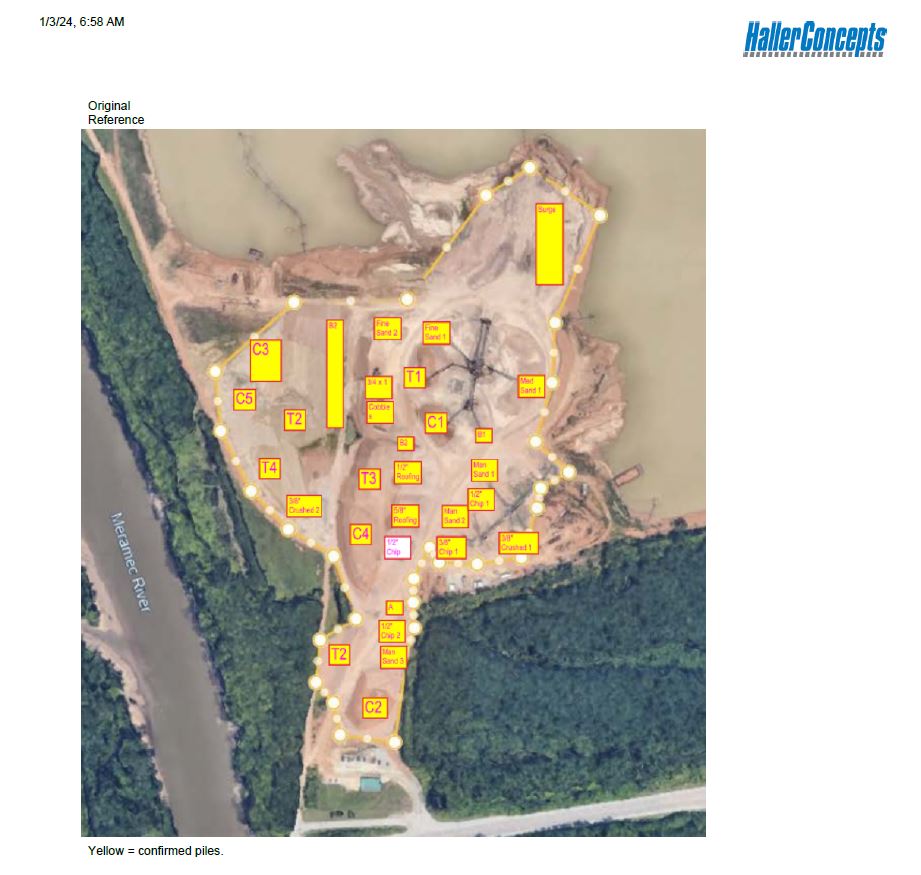

This step is where many projects succeed or fail. The best reporting starts by agreeing on:

- Which piles count (and how they’re named)

- Where pile boundaries are drawn

- How the base surface is defined (ground plane, pad, or reference model)

- Desired reporting cadence (weekly, monthly, quarterly)

- Required outputs (PDF report, CSV volumes, CAD surfaces, orthomosaic, etc.)

You’re not buying “a drone flight.” You’re buying a measurement system.

2) Flight Planning for Clean Coverage

A LiDAR stockpile flight is planned around:

- consistent altitude and overlap

- safe standoff from structures and operations

- coverage angles that reduce occlusions (important near conveyors or tall piles)

- timing to minimize traffic conflicts and maximize visibility

3) Control and Georeferencing (The “Trust Layer”)

Accuracy depends on how well the data is tied to reality. Depending on your required precision, a workflow may use:

- RTK/PPK positioning

- ground control / checkpoints

- existing site benchmarks

A serious provider should be able to explain:

how the data is referenced, how it’s verified, and what the expected error range is.

4) Processing: From Raw Point Cloud to Usable Volumes

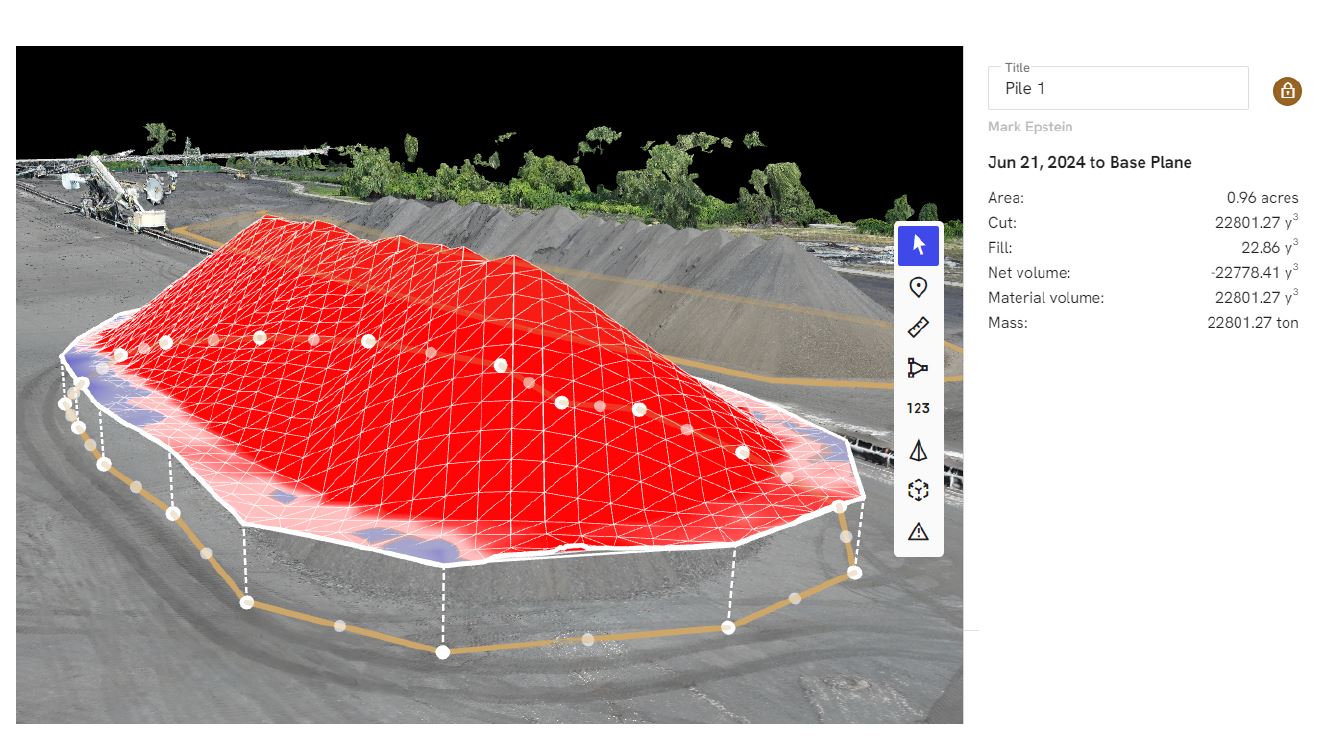

After the flight, LiDAR data is processed into:

- classified point clouds (ground vs non-ground)

- digital terrain models (DTM)

- digital surface models (DSM)

- pile segmentation surfaces

Then volumes are computed using a defined base surface and boundary polygon for each pile.

5) Reporting: Executive-Friendly and Audit-Friendly

A professional stockpile report should be readable by operations and defensible for finance.

Expect things like:

- pile ID / name

- measured volume (with units)

- date/time of capture

- maps or annotated visuals showing boundaries

- change over time (optional but powerful)

- data exports for ERP/accounting integration

Why LiDAR Makes Stockpile Reporting Easier

Fewer Re-Measurements and Less Second-Guessing

The biggest hidden cost in stockpile measurement isn’t the first number—it’s the argument that follows.

LiDAR helps reduce:

- “That number feels off…”

- “We measured it differently last month…”

- “The pile footprint changed…”

- “We can’t reproduce that method…”

Better data reduces internal friction.

Less Disruption to Operations

You’re not shutting down loaders or moving people into hazardous zones for hours. With drone capture, you can often document the site quickly, then do the heavy lifting in processing.

A Repeatable Cadence That Fits Business Rhythms

Most organizations don’t need heroic one-time surveys. They need reliable measurement on a schedule:

- month-end close

- quarterly inventory

- post-storm washout assessment

- pre/post shipment validation

- dispute resolution documentation

LiDAR drone workflows scale naturally into repeatable reporting.

Where LiDAR Shines in the Real World

LiDAR tends to outperform (or simplify) reporting when you have:

- complex pile geometry (steep slopes, multiple lobes, stacked piles)

- busy sites with lots of equipment, structures, and occlusions

- low-contrast materials (coal, wet sand, dark aggregate)

- variable lighting (deep shadows near walls or conveyors)

- tight reporting deadlines (month-end, audit windows)

- multi-site standardization needs (same process everywhere)

What to Ask a Provider Before You Buy Anything

If you’re evaluating LiDAR stockpile services, these questions separate professionals from hobbyists:

- How do you establish accuracy and verify it?

Look for checkpoints, QA notes, and an explanation you can pass to finance. - How do you define pile boundaries and base surfaces?

If the method changes each time, your trendline becomes meaningless. - What deliverables do you provide—and in what formats?

Ask for sample reports, CAD exports, and a volume spreadsheet template. - What’s your workflow for repeat monthly reporting?

You want a process, not a one-off. - How do you handle safety and operational coordination?

A professional team works around your site, not against it.

Turning LiDAR Stockpile Reporting Into a Strategic Advantage

Once you have a repeatable LiDAR reporting pipeline, you can start doing more than just measuring piles.

You can:

- monitor shrinkage and loss over time

- validate vendor quantities more confidently

- optimize site layout and material flow

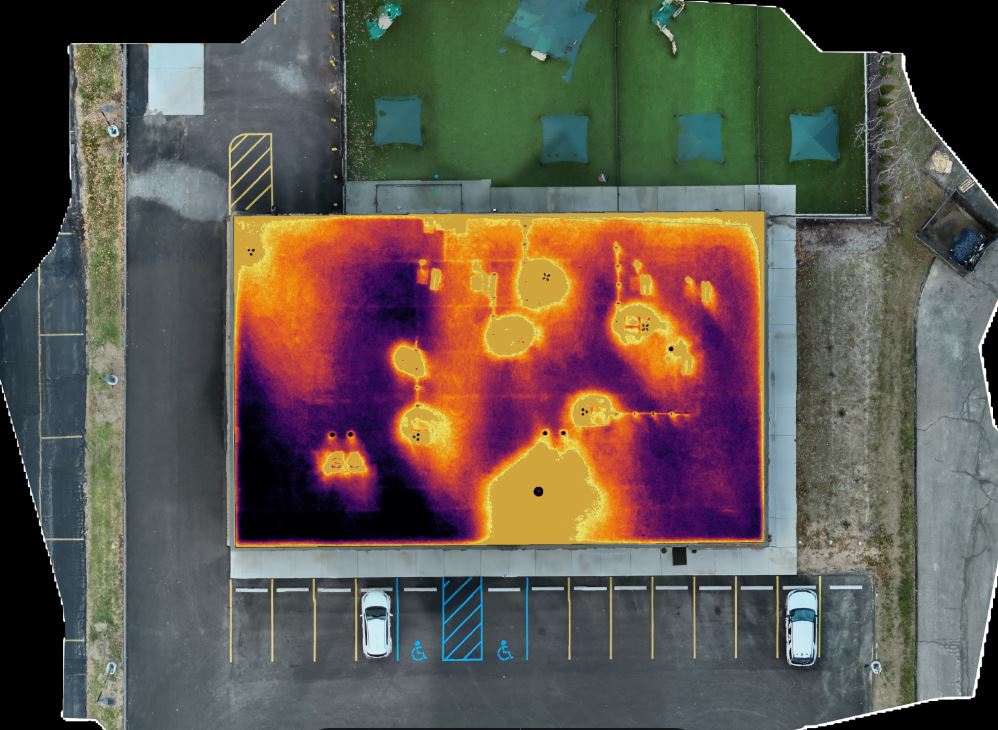

- document storm damage and erosion

- create 3D site models for planning and marketing

- produce visuals that support proposals, audits, and stakeholder updates

The same dataset can serve operations + finance + leadership + marketing when it’s captured correctly.

Why St. Louis Drones Is Built for This Work

At St. Louis Drones, we approach LiDAR stockpile reporting like we approach any high-stakes production: with planning, repeatability, and deliverables that hold up under scrutiny.

We’re a full-service professional commercial photography and video production company with the right equipment and experienced creative crew for successful image acquisition. We provide full-service studio and location video and photography, plus editing and post-production, and we operate with licensed drone professionals. We customize productions for diverse media requirements, and we specialize in repurposing photography and video branding to help your content travel farther and work harder across platforms.

We’re well-versed in all file types, media styles, and the software ecosystems businesses and agencies rely on. We also use the latest Artificial Intelligence tools across our media services—supporting smarter workflows, faster turnarounds, and scalable production pipelines.

Need indoor capture? We can fly specialized drones indoors when a project requires tight spaces, complex environments, or controlled conditions.

And we’re not new to serving demanding clients. As a full-service video and photography production corporation since 1982, St. Louis Drones has worked with many businesses, marketing firms, and creative agencies across the St. Louis area—bringing the same production discipline to industrial measurement, corporate marketing, and everything in between.

If your organization needs stockpile reporting that’s easier to run, faster to deliver, and more reliable to trust, LiDAR drones can turn a chronic problem into a clean, repeatable process—and we can help you implement it end-to-end.