As experienced producers in the competitive St. Louis market, we recognize that the demand for high-quality video content is insatiable. Marketing directors and business leaders are under constant pressure to deliver visually arresting narratives across multiple platforms, often with tightening budgets.

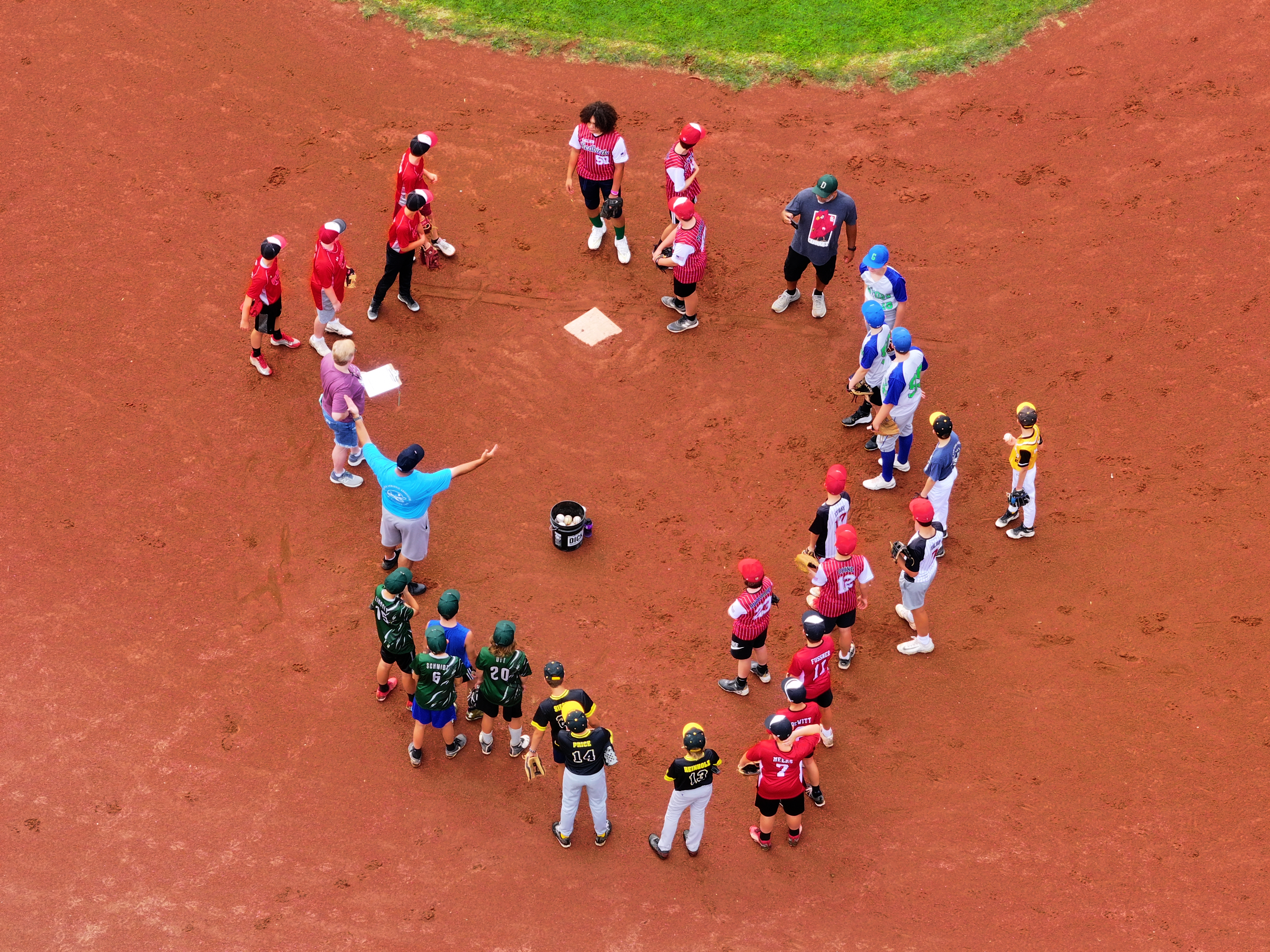

In corporate, industrial, and commercial video production, the narrative backbone—the interviews or scripted messaging—is often called “A-Roll.” But the soul of the production, the elements that provide context, visual engagement, and cinematic production value, is the “B-Roll.”

Historically, acquiring high-end, dynamic B-Roll—especially aerials or sweeping motion shots—was distinctively not cost-efficient. It required helicopters, expensive jibs, extensive track systems, and large, specialized crews. Today, professional drone technology has democratized this cinematic quality, but only when deployed by experienced operators.

This article addresses how utilizing specialized, local St. Louis drone crews for B-Roll acquisition is no longer just a stylistic choice—it is a strategic, cost-efficient business decision.

The New Economics of Cinematic Acquisition

For decision-makers, “cost-efficiency” doesn’t mean “cheap”; it means maximizing the return on every production dollar spent.

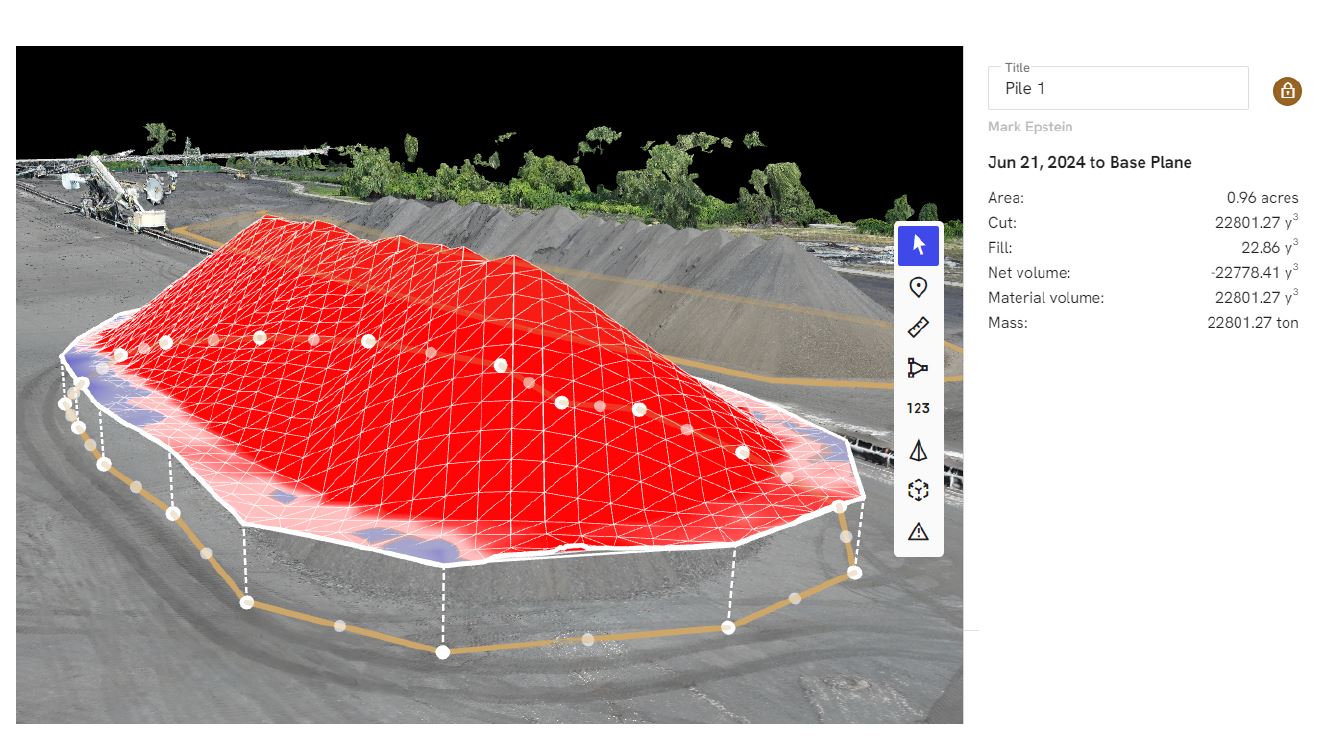

A professional drone team replaces tons of legacy equipment. Where a sweeping shot of a manufacturing facility once required renting a boom lift or a piloted aircraft, a two-person certified drone crew can capture the same shot—often with greater stability and lower altitudes—in a fraction of the time and cost.

Furthermore, the speed of acquisition is unparalleled. A skilled drone operator and visual observer can relocate rapidly across a corporate campus or industrial site. We can capture establishing shots of the exterior, dynamic tracking shots of fleet vehicles, and revealing architectural movements all within a single battery cycle. This speed translates directly to reduced crew hours on site and more footage in the can.

Beyond the Sky: Specialized Indoor Applications

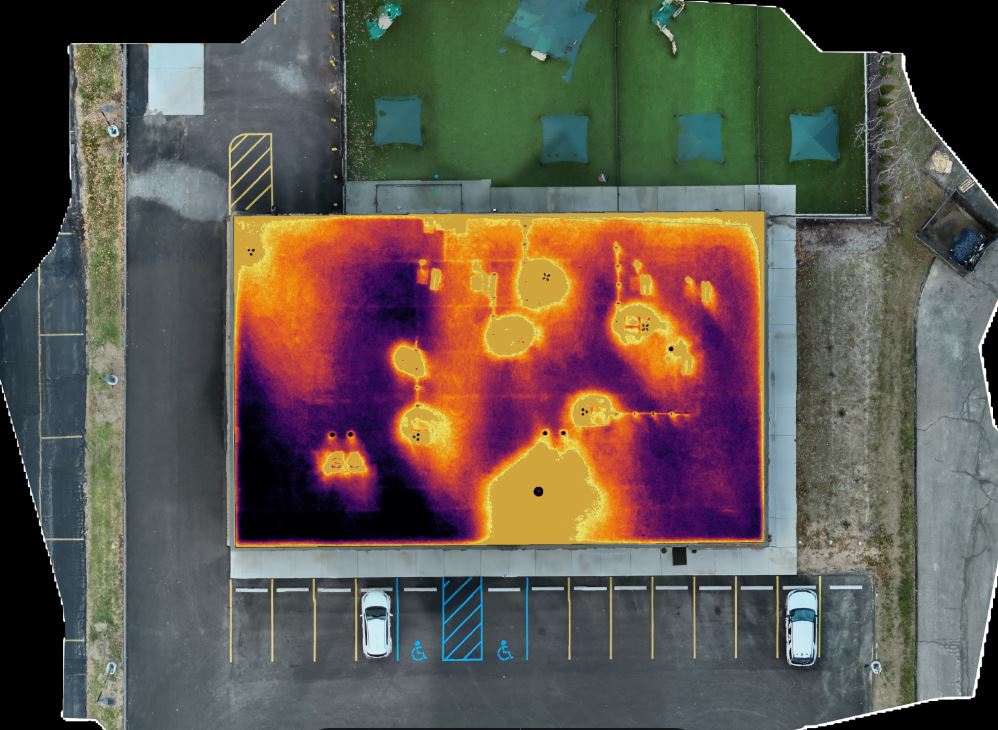

A common misconception among our commercial clients is that drones are solely an outdoor tool. This is outdated thinking.

Modern, specialized drones—often referred to as “cinewhoops” or guarded-propeller aircraft—have revolutionized indoor B-Roll. We can now fly cameras safely through active warehouses, along assembly lines, through real estate developments, and inside large office atriums.

This capability allows for seamless transitions from exterior grandeur to interior detail in a single, fluid movement. It provides a “fly-on-the-wall” perspective that standard ground cameras simply cannot achieve, adding immense production value to facility tours or operational overview videos without disrupting the workflow on the ground.

The Importance of the “Local” Crew

When budgeting for a production in the St. Louis region, utilizing a local, experienced drone team immediately eliminates significant line items: travel costs, lodging, and per diems for out-of-town specialists.

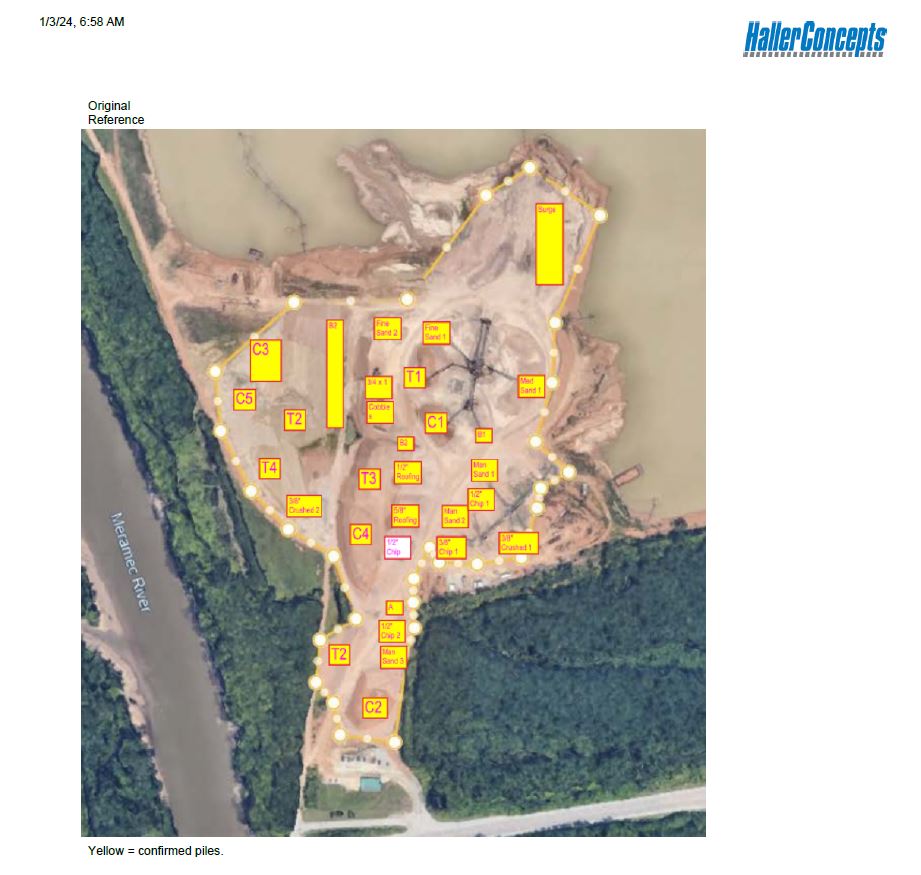

More importantly, local knowledge is an operational asset. As long-standing St. Louis producers, we understand the specific airspace regulations overlapping the metro area, from Lambert International to regional airports. We know the lighting conditions at specific times of day for key local landmarks and industrial zones. This local expertise ensures faster permitting, safer flight planning, and more efficient shoot days.

The Professional Difference: Why Experience Matters

While the technology is accessible, high-level B-Roll acquisition is an art form requiring professional discipline. It is not merely about flying a drone; it is about understanding composition, camera movement, lens choices, and how a specific shot will edit into the final sequence.

An experienced producer knows that B-Roll must serve the story, not just look pretty. We approach drone cinematography with the same rigor as traditional camera work, ensuring the footage we capture integrates seamlessly with ground-based cameras in terms of color science, frame rate, and resolution.

St Louis Drones: Your Full-Service Production Partner

While specialized drone B-Roll is a powerful tool for efficiency, it is usually just one component of a successful marketing campaign. You need a partner who understands the entire production ecosystem.

St Louis Drones is more than just an aerial provider. We are a full-service professional commercial photography and video production company with deep roots in the industry, serving businesses, marketing firms, and creative agencies in the area since 1982. We possess the right equipment, creative crew service experience, and logistical know-how for successful image acquisition across any terrain.

We support every aspect of your production to ensure a seamless experience. Our capabilities extend far beyond aerials:

- Full-Service Studio and Location Production: Whether on-site at your facility or in our controlled environment, we handle all aspects of video and photography.

- Private Studio Facilities: Our private studio offers professional lighting and visual setups perfect for small productions and interview scenes. The space is large enough to incorporate props to round out your set, providing a controlled environment for pristine audio and video capture.

- Comprehensive Post-Production: We offer end-to-end editing and post-production services. We are well-versed in all file types, media styles, and accompanying professional software.

- AI Integration: We utilize the latest in Artificial Intelligence tools throughout our media services to enhance workflow efficiency, footage culling, and post-production processes.

- Content Repurposing: A successful shoot shouldn’t just yield one video. A specialty of ours is repurposing your high-quality photography and video branding across diverse media requirements to gain more traction on social media, websites, and internal communications.

From supplying professional sound and camera operators for a ground shoot to flying specialized drones indoors for unique perspectives, St Louis Drones has the experience and technology to execute your vision cost-effectively.

Rob Haller 314-604-6544 stlouisdrones@gmail.com